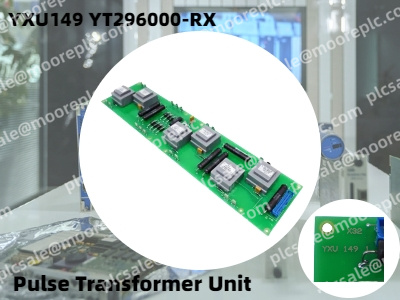

Introduction ABB YXU149 YT296000-RX pulse transformer unit is an indispensable key component in industrial automation and high-voltage switch systems. As a special component, the device can achieve accurate electrical signal transmission in complex control circuits. As a leader in automation technology, ABB's YXU149 series has attracted much attention due to its precision manufacturing, durability and wide applicability. This article will explore the core functions, design advantages and applications of this pulse transformer unit in various industrial scenarios. Pulse Transformer Technology and Its Importance The pulse transformer is an electrical component specially designed for transmitting high-speed, short-duration pulse signals. It is widely used in trigger circuits, digital logic interfaces, power conversion and signal isolation. The YT296000-RX model is a high-performance pulse transformer designed for high-precision timing and signal isolation, especially for industrial control and electrical switch operation. It has the ability to process high-frequency and high-voltage signals, effectively reducing interference and signal distortion, which is particularly important in industrial environments with strict requirements on accuracy and safety. The pulse transformer uses a ferrite core, which has excellent magnetic efficiency and low loss characteristics. At the same time, it realizes effective electrical isolation between the control circuit and the power circuit to ensure safe and stable operation of the system. Main features and design advantages The YXU149 YT296000-RX pulse transformer unit fully reflects ABB's strict requirements for industrial quality in design, and has the following key features: High insulation withstand voltage capability: It can withstand higher isolation voltage and is suitable for industrial environments with frequent voltage shocks. Low leakage inductance design: It greatly reduces leakage inductance and improves the fidelity and rise time accuracy of the pulse. Compact structure design: It is small in size and easy to install in control cabinets and modular systems. Strong thermal stability: It can maintain stable operation in a wide temperature range and adapt to harsh working conditions. Durability and long life: The rugged packaging design is moisture-proof, dust-proof and vibration-proof. In addition, the optimized winding structure and material selection improve the coupling efficiency, further improving the conversion efficiency and circuit response speed. Industrial Application and Integration Method ABB YT296000-RX pulse transformers are widely used in scenarios with high requirements for signal integrity and system reliability, including: High-voltage switch control system: Realize accurate transmission of pulse control signals in high-voltage switches to ensure reliable switch action. Power plant automation: Applied to circuit isolation signal transmission in turbine control and ...

Read More

IPv6 network supported

IPv6 network supported