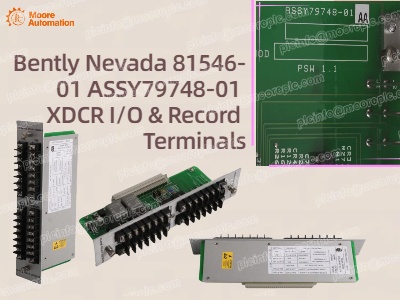

Bently Nevada 88286-01J: A Strong Connector for Watching Factory Machines In today's factories that use a lot of automation, it's very important for the machines to work without problems and for the systems that watch them to be efficient. Bently Nevada, a well-known company that provides ways to watch and protect machines, has just released a new product called the Bently Nevada 88286-01J Terminal Board. This new board is getting a lot of attention because it helps make these monitoring systems even better. Key Part: Steady Connection, Exact Sending of Information The Bently Nevada 88286-01J Terminal Board is a special board used to connect the parts that collect information from machines to the main computer that watches them. It's very important because it helps the electrical signals travel correctly and makes sure the whole system is stable and safe. The design of the 88286-01J is made to work well in tough factory environments and is very good at stopping interference and working reliably. Main Benefits Help Factories Improve Works with Many Systems: The 88286-01J Terminal Board can connect easily with different Bently Nevada monitoring parts, especially the 3500 series system. This makes it easier to add more to the system and set it up in different ways. Made with Good Materials, Strong and Dependable: This terminal board is made with high-quality materials that are used in factories. It can handle heat, resist damage from chemicals, and won't wear out easily. This means it can work steadily for a long time in difficult conditions like high temperatures and humidity. Easy to Install and Fix: The way the wires connect is simple, which makes it easier to set up the system in the factory. It also makes it easier to fix or replace parts later, which saves money on maintenance and reduces the time machines are not working. Sends Information Steadily: The way the circuits are designed helps reduce interference with the signals. This makes sure the information that is used to watch the machines is accurate and in real time. This reliable information is important for warning about problems and seeing trends. Used in Many Industries, Helps Different Businesses Grow: The Bently Nevada 88286-01J Terminal Board is used in systems that watch important machines in industries like oil and gas, power, chemicals, steel, and cement. Whether it's big spinning machines like turbines and compressors, or very precise motors and pumps, this terminal board provides a safe and steady way to connect to the data collection system. In wind power plants, the 88286-01J also works very well and stays reliable for a long time. This helps renewable energy equipment work smartly and be watched from far away. Meets the Needs of Smart Factories and Leads the Way As factories become more automatic and smart with Industry 4.0, the systems that watch the machines need to be even better. The 88286-01J terminal board from Bently Nevada not only meets the basic needs of tradition...

Read More

IPv6 network supported

IPv6 network supported